KiSSAM Simulation Software for Additive Manufacturing

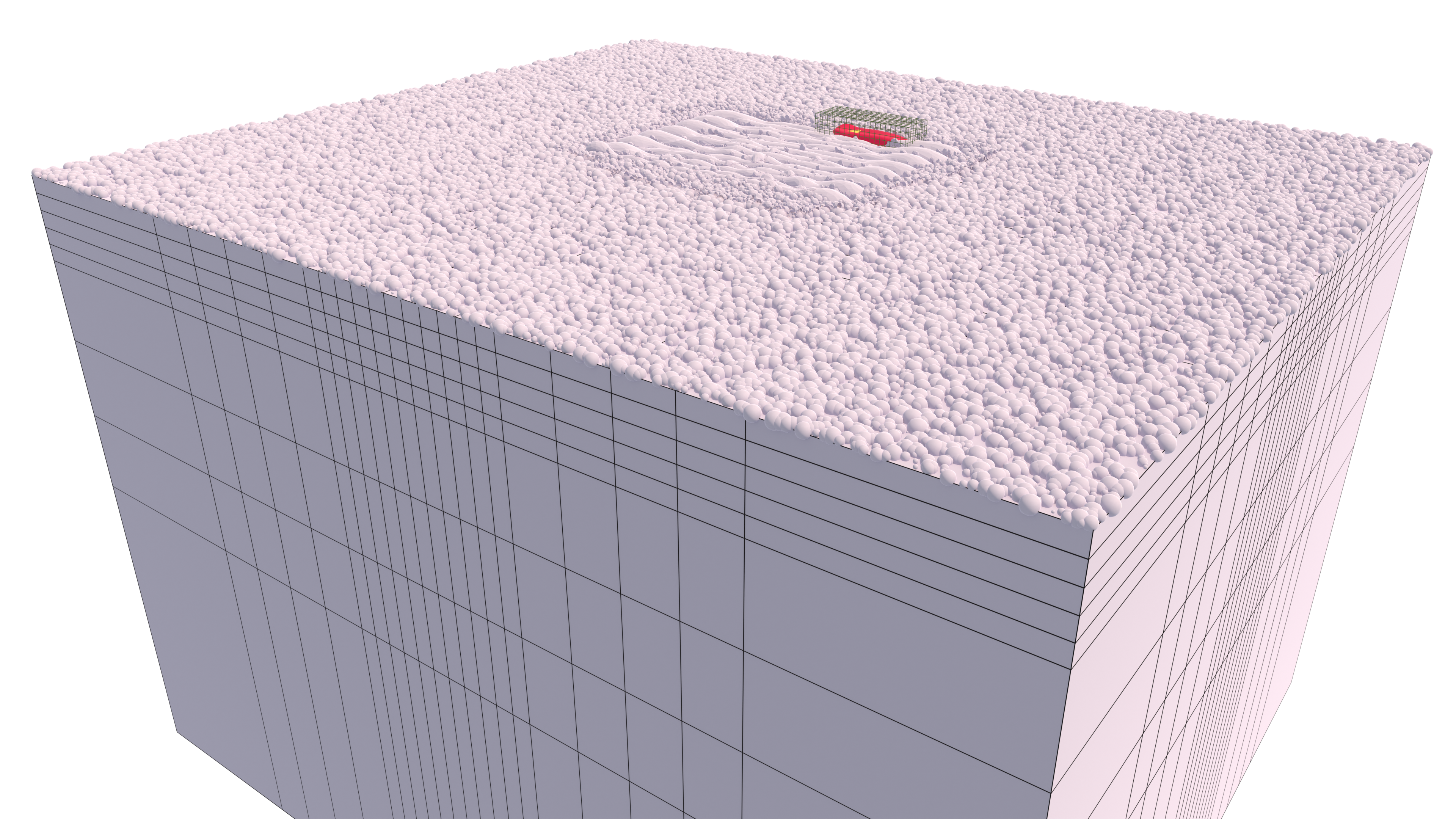

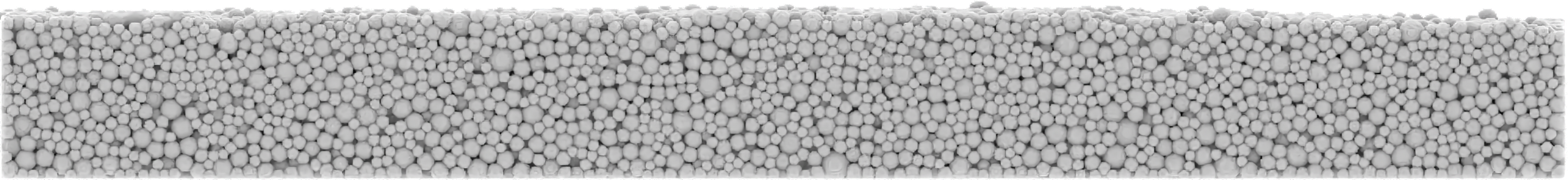

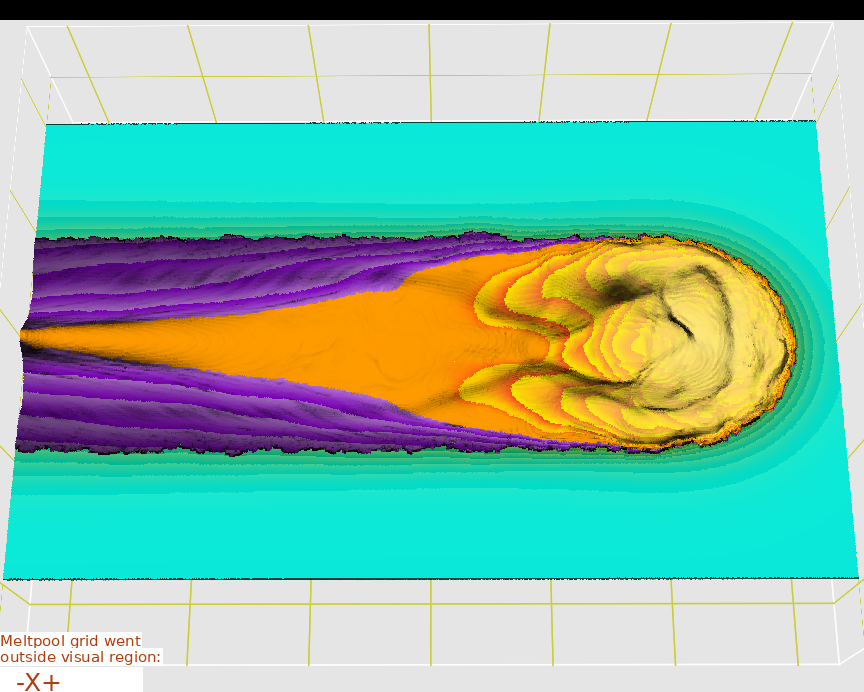

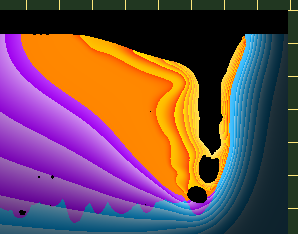

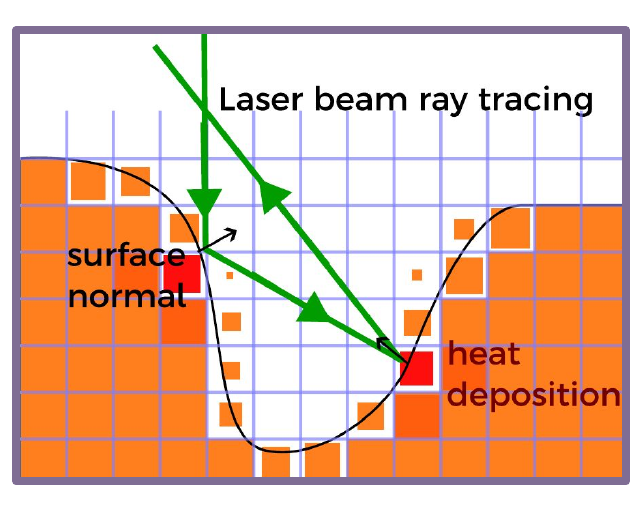

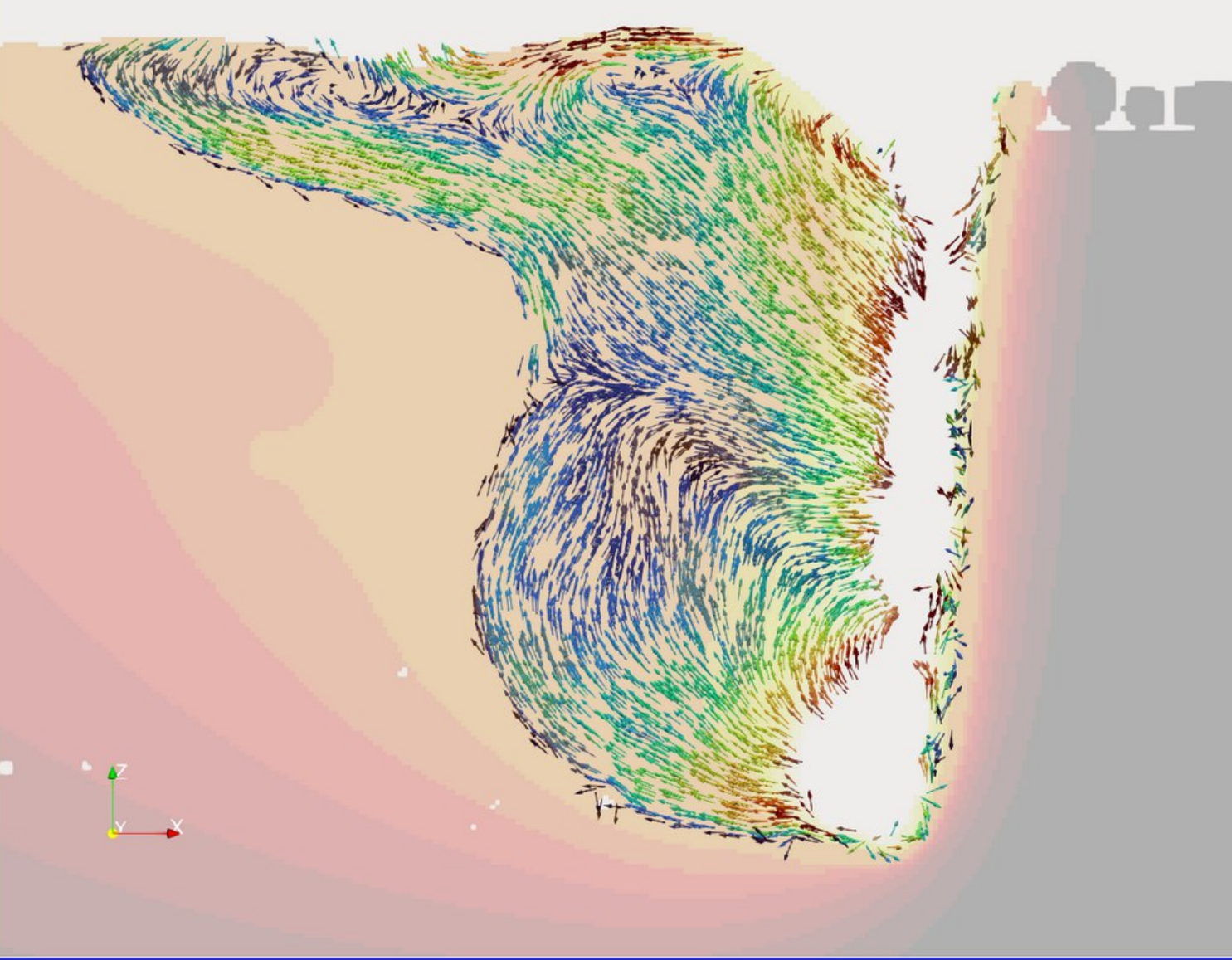

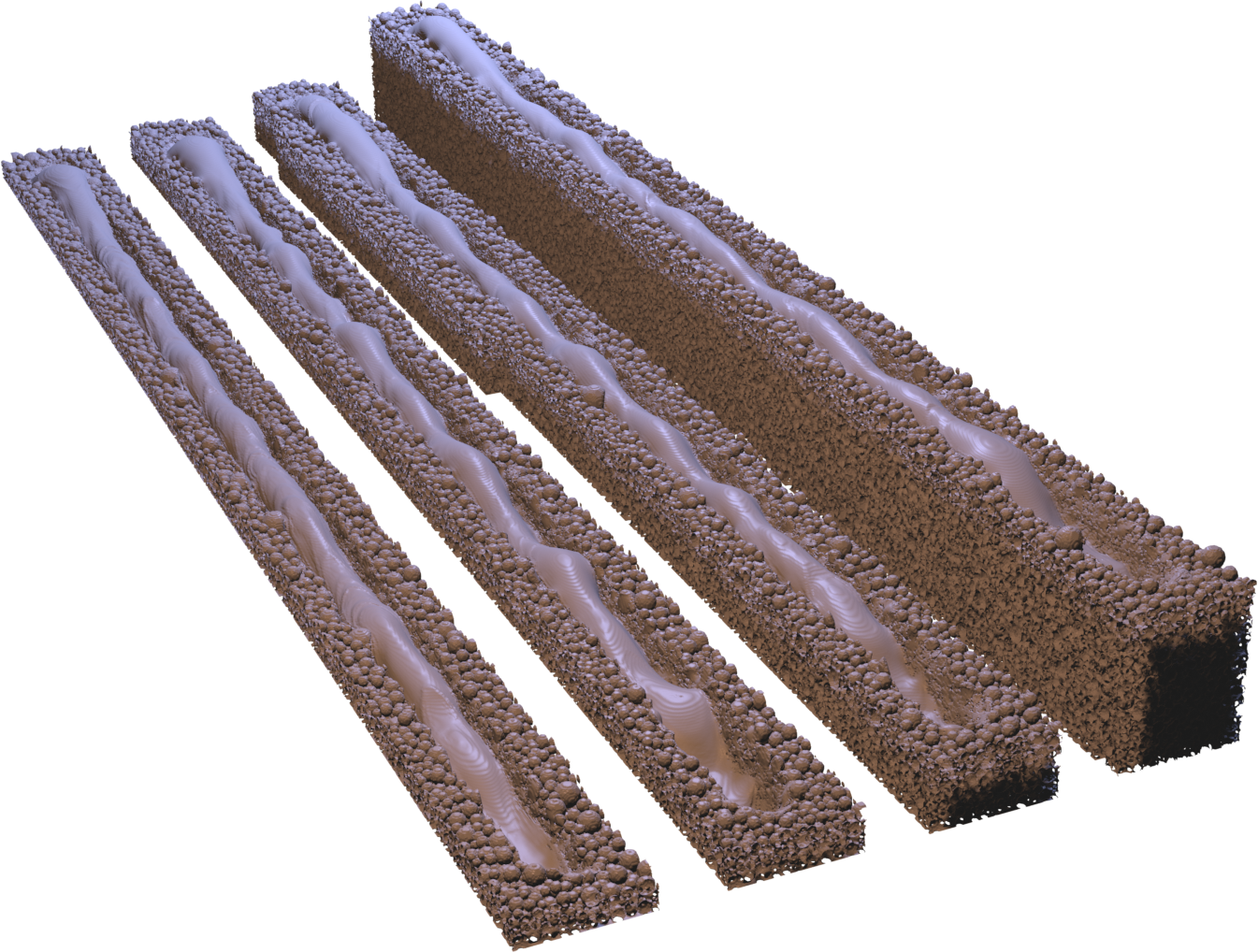

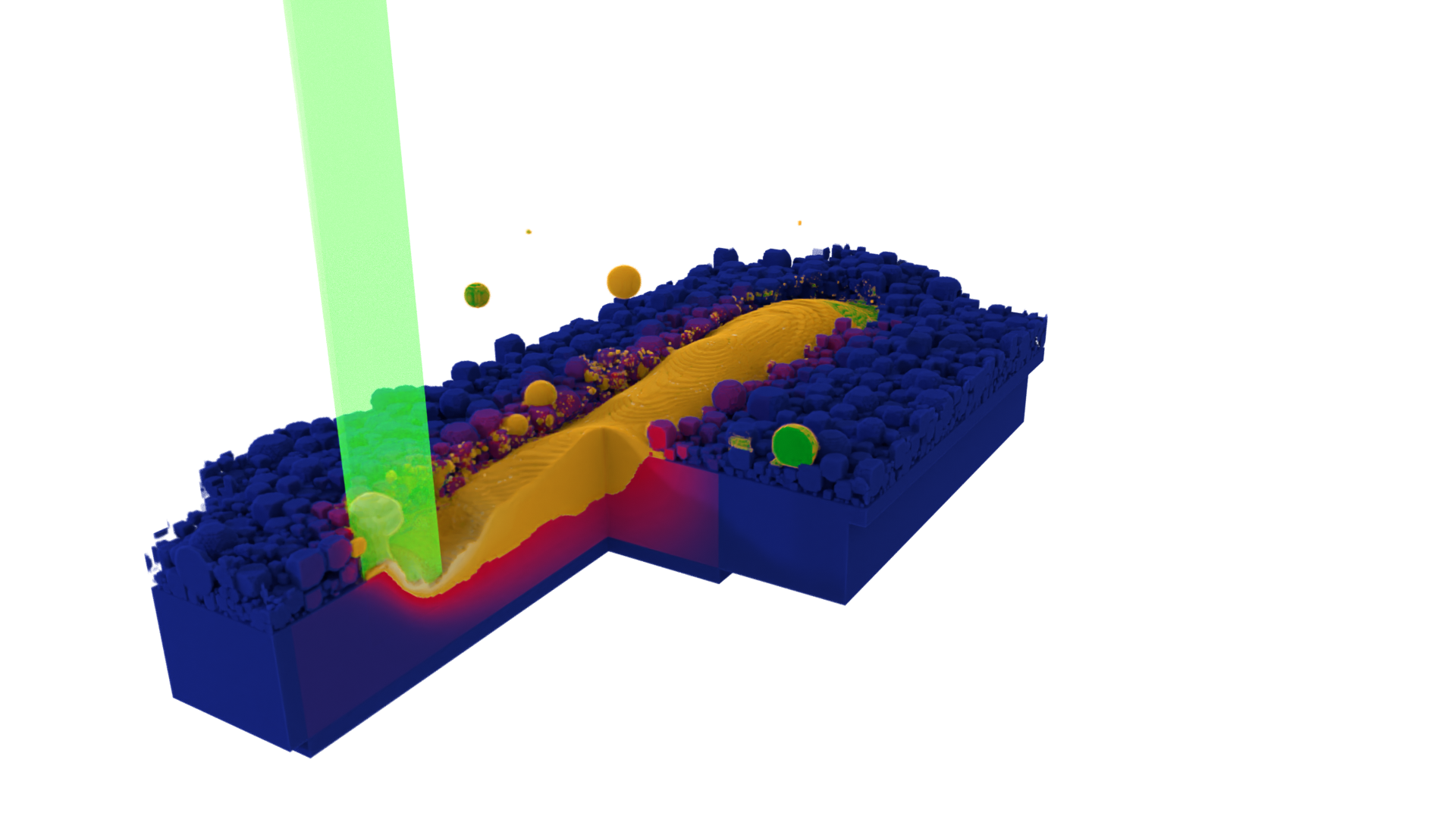

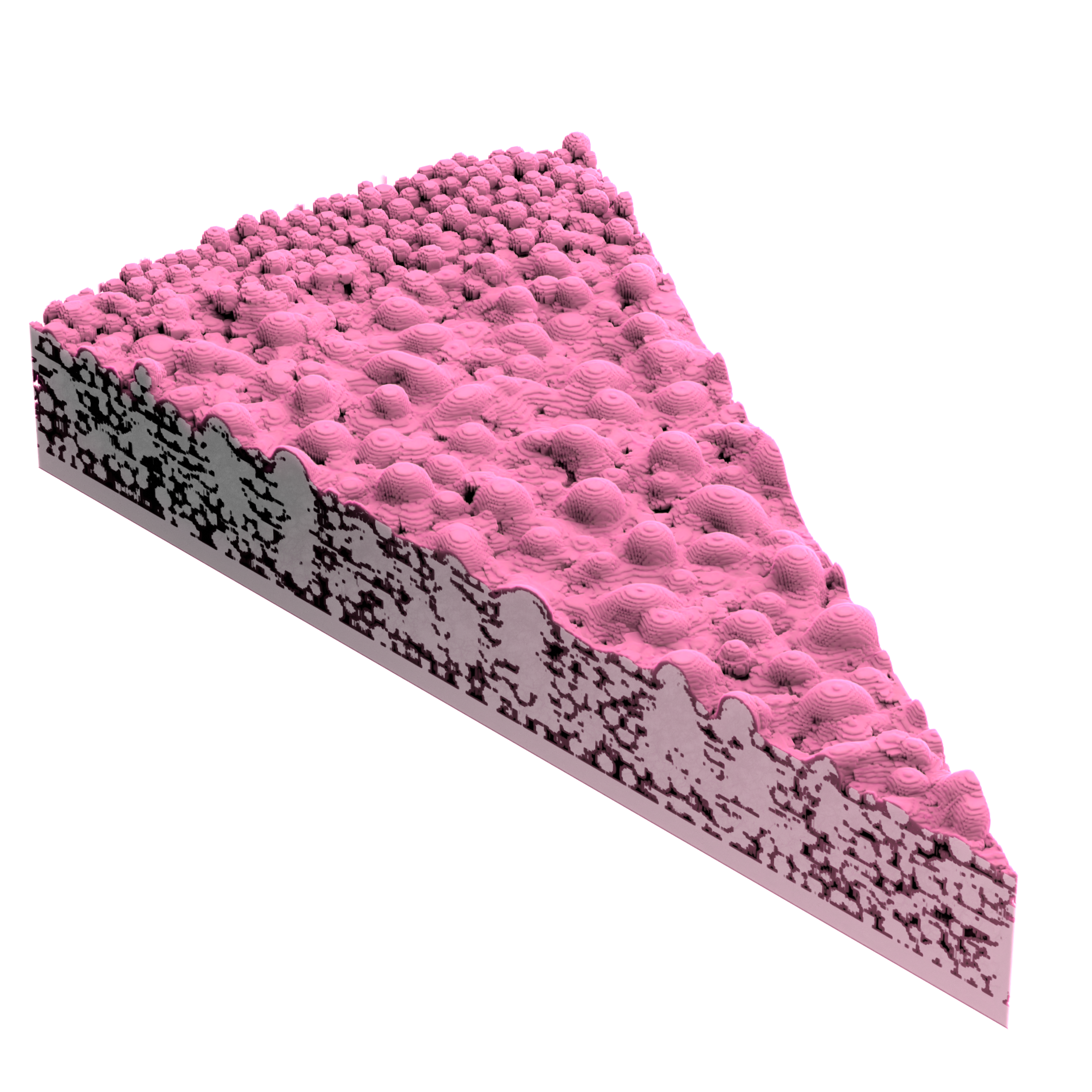

KiSSAM is a simulation package for CUDA GPU that is built around a fluid dynamics code tailored specifically for melt pool modeling. Track morphology is accurately reproduced due to the careful account of all relevant surface effects on a fine mesh. The models of heat deposition for electron beam and laser source are implemented. The heat transfer is simulated, and energy dissipates through models of radiation, convection, and evaporation.

FREE TRIAL

Fill in the Form to get free access to the trial version on the web.It works as a cloud service.

Experience the high performance by running your own simulations.

WHY MESOSCALE?

Identify scanning regime defects: balling, keyholing, etc. Inspect melted sample morphology: roughness, porosity. Virtually build overhangs, thin walls, fine structures. Get temperature history, portion of absorbed energy.

HIGH PERFORMANCE

On a desktop workstation with at least one high-end GPU:- Simulate in full 3D

- Resolve small powder particles, sintering and pores on a fine mesh

- 0.5 ~ 1 hr of simulation per 1 ms scanning time

- Multi-layer simulations

- Get detailed process maps (hundreds of experiments) in a few days