Laser Hatched Layer with Powder Layer¶

Goal¶

A powder bed over a plate of SS316L is taken as an initial geometry. The Gaussian laser pulse with normal incidence melts the metal, and hatches a layer.

Powder generation is possible in KiSSAM, but it takes simulation time. When powder is set on a flat substrate, the same powder can be reused in different simulations. In this sample simulation, we use powder layer that was generated before. It should be in a vdb format, with mesh size that corresponds to the simulation setting.

Run¶

Copy the JSON file provided with the usercase into the simulation folder, and the powder layer file, into the simulation folder.

> cp <path>/Laser_layer_powder.json .

> cp <path>/init_spheres.vdb .

Run the code from terminal with the provided JSON file. You may need to edit the information on the license file in it.

> INPUT_JSON_FILE=Laser_layer_powder.json /opt/KiSSAM/start_calc.sh

Make sure that simulation is started by making sure there are no fatal errors in the .log file that has appeared.

It might be necessary to insert the correct license filepath.

Input Configuration¶

The simulation parameters can be adjusted by editing the JSON file.

1{

2 "licenseFile": "/licences/kissam-end-2023-6-30.lic",

3 "outputDir": "./output/",

4

5 "config": {

6 "MaxTimesteps" : 2000000,

7 "AutoTermination" : true,

8 "DumpDataRate" : 500000,

9 "IterationSubstepsRate": 1000,

10 "DumpVTK" : true,

11 "DumpVDB" : true,

12 "DumpARR" : false

13 },

14 "sizes": {

15 "FullXapprox": 0.003,

16 "FullYapprox": 0.003,

17 "FullZapprox": 0.005,

18 "substrate" : 0.00456

19 },

20

21 "Powder": {

22 "initSpheresVDBfile": "init_spheres.vdb",

23 "wettingAngle": 150

24 },

25

26 "Substrate": {

27 "preheating" : 300.0,

28 "wettingAngle": 10

29 },

30 "Material": "SS316L",

31 "ScanStrategy": {

32 "Type": "SquareLayer",

33 "SquareLayer": {

34 "startPosX": 0.5e-3,

35 "startPosY": 0.5e-3,

36 "dimX" : 2e-3,

37 "dimY" : 2e-3,

38 "hatchX" : 0,

39 "hatchY" : 100e-6,

40 "delayBetweenTracks": 0

41 },

42 "Beam": {

43 "type" : "Laser",

44 "Power" : 150.0,

45 "Width" : 55e-6,

46 "Speed" : 1.20

47 }

48 }

49}

The parameters that are not specified here are taken from the /opt/KiSSAM/default.json file.

Simulation Results¶

The simulation runs for ~18 hours. The default name for the simulation output directory is output.

3D view¶

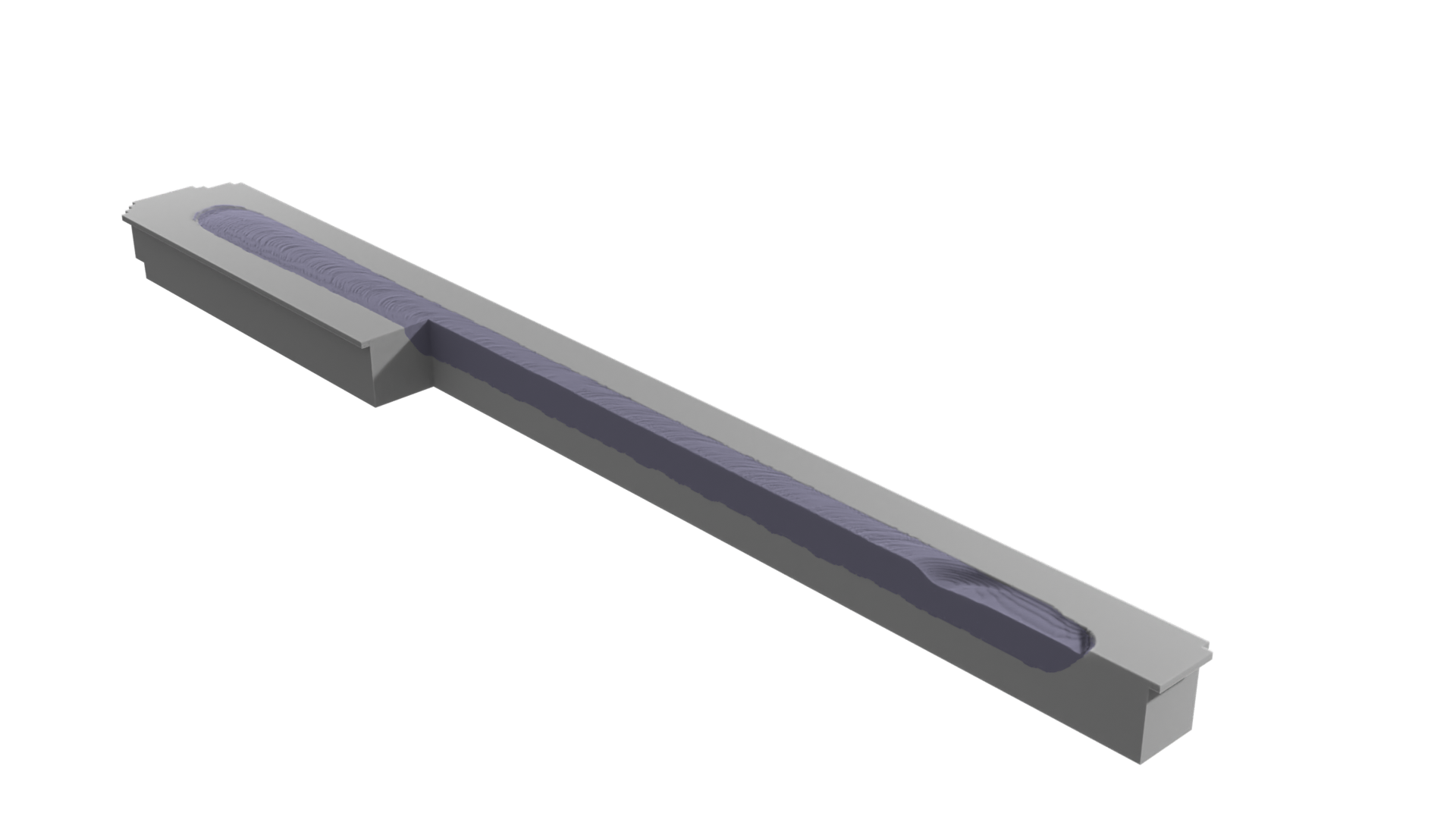

The track geometry is stored in the openVDB format output/geometry.vdb.

It is updated during the simulation process and stores the latest state.

View it with Blender or VDB view.

Fig. 44 openVDB file loaded and rendered in Blender¶

Images and animation output¶

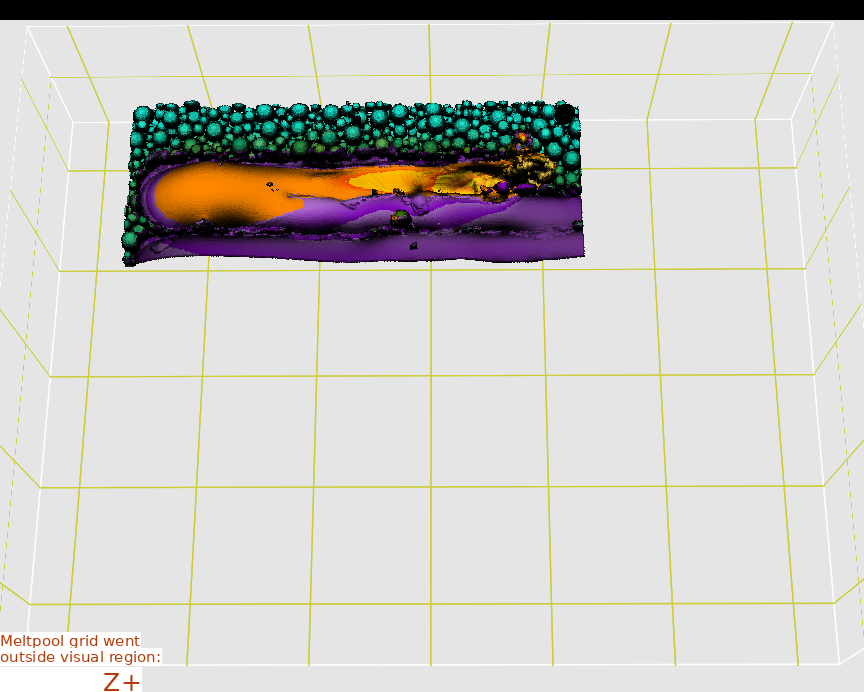

The meltpool states are rendered as images and stored in output/rendered3D.

The images of cross-sections are found in output/cross-sections.

Fig. 45 Example of the combined image combinedIMG/pic-250000.png¶

Surface analysis¶

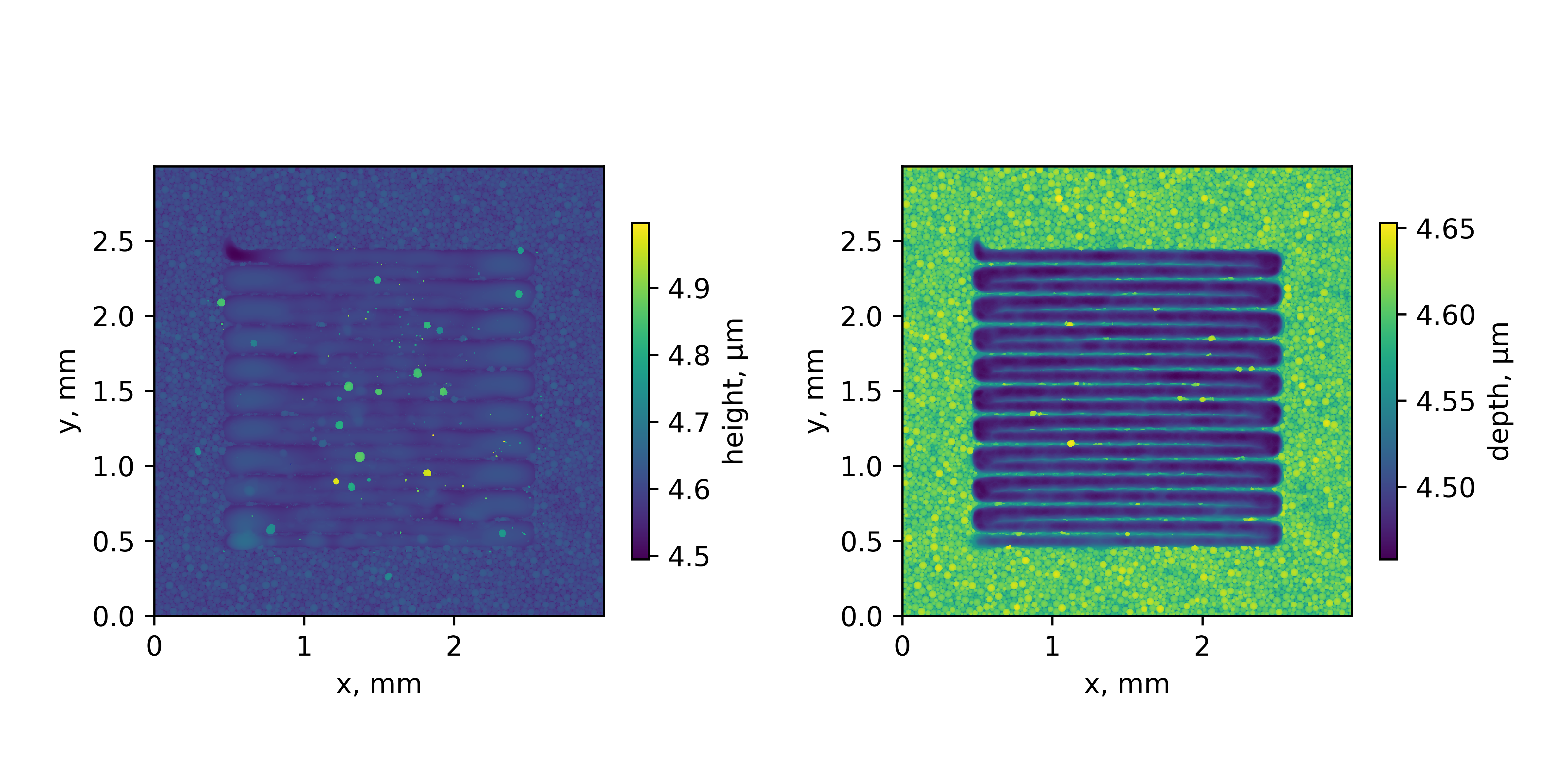

In the simulation folder, run the script generating file geometry data in text format:

> /opt/KiSSAM/scripts/surfaceAnalyzer.x output/geometry.vdb > heights.dat

The output is the text file heights.dat.

#units: millimeters

#Xcoord Ycoord SurfaceHeight MeltpoolDepthPosition

0 0 4.56 4.56

0.003 0 4.56 4.56

0.006 0 4.56 4.56

0.009 0 4.56 4.56

0.012 0 4.56 4.56

0.015 0 4.56 4.56

0.018 0 4.56 4.56

0.021 0 4.56 4.56

...

Here we plot the third and the fourths columns as a colormap

Fig. 46 Surface information plotted in the xy plane¶

Cross Section Image¶

Let us run this script to extract cross-section at \(x=1.5\) mm from the track start startPosX (\(1\) mm):

> /opt/KiSSAM/scripts/drawCrossSection.x output/geometry.vdb trackXcrossSection.png --box 2.5,1.91,4.4867 2.5,2.09,4.6 --background E8F0F200 --substrate 295569FF --remelted CD86F2FF

One pixel of the image is one mesh step: NumericalParams.dr (3 μm) in the input file.

Fig. 47 Cross section in simulation¶